What’s it all about then?

Simon Tolley, our Director & Senior Mechanic, shares a few thoughts and tips on the “good ole rear derailleur hanger”.

So – “Rear Derailleur Hangers,” “Gear Mech Hangers,” “Dropouts,” “Frame Savers,” – call them what you will, are a lifesaver. They are usually made of an alloy; a relatively soft material, cast, stamped, cold-forged or CNC Machined.

They attach to your bike by bolts, screws or both, from inside or outside the frame. The actual rear derailleur itself then bolts to this mech hanger.

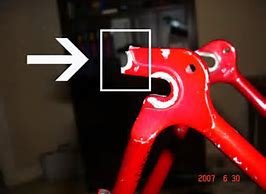

There are hundreds if not thousands of different types of rear hangers. You will find that some hangers fit an enormous number of different manufacturer frames and multiple frame years, like our CC007, pictured here.

Some models are, however, specific to one manufacturer’s frame and even the specific year of manufacture, meaning that a manufacturer could change the hanger each year for essentially the same frame, which hinders trying to source your replacement.

Mech hangers are, of course, a sacrificial part designed and fitted for the purpose of bending and/or breaking under stress to reduce or eliminate damage to your frame and drivetrain parts. As a result, it is an impossible part to warranty. Successful breakage pictured here.

A bent or broken rear mech hanger is an extra expense and a pain but is very minor compared to the cost of repairing or replacing your frame or damaged drive-train components. It is also much less expensive than snapping an in-built hanger on an older style steel frame, like this example here…

This essentially renders the frame useless. Hence the reason rear mech hanger exists and as the title says – “that’s what it’s all about!”

An everyday analogy that better explains a rear derailleur hanger’s purpose would be that the sacrificial hanger is akin to a fuse within a plug inside an electrical appliance. When overloaded, the fuse is designed to blow. The fault can then be checked, diagnosed and remedied where applicable. The fuse can then be replaced and equipment set up and tested fully before use.

We all need to avoid the chances of breakage as best we can. Many risks can potentially be avoided but many can’t, as there are everyday risks encountered while riding. Crashes perhaps, being the principal one.

So what should we reduce or avoid? Some go without saying, but we’re not always able to do it. Crashing, potholes, poor gear shifts, just being in the wrong gear particularly when climbing or on stationary starts are good examples of what to avoid or take care with.

Many reasons are potentially homegrown from poor maintenance issues. Experience points the finger at incorrectly fitted or worn chains, debris caught up in links, a chain that is too long or short for the crankset, rear mech and cassette combinations fitted. Not setting limit screws and having incorrectly indexed gears is another.

Lots of these can be removed as risks with good maintenance. Left alone they can cause undue stress on your gear hanger.

Some of these examples are when drive-train parts are placed under some of the greatest load, creating massive stresses on the component parts ie. chain, rear derailleur, crankset and so on.

Simply keeping our component parts clean, free of debris, detritus and lubing them where necessary will go a long way to preventing catastrophe.

How many times have you caught grass, twigs, road gravel or tarmac in your chain and drivetrain parts? How long has it stayed there? How many times have you removed parts, used a degreaser bath and thoroughly cleaned them, or had your LBS do it for you? Not at all? Once? It comes as no surprise that whether your bike is a work hack, weekend warrior or carbon steed, it will suffer as a result.

Then you begin to realise why rear mech hangers exist and sacrifice themselves when necessary.

It’s a favourite pass-time to blame a part like a gear hanger for an incident. Think twice. When the gear hanger bends or breaks under load it is paying for our riding environment, riding habits, lack of maintenance, mechanical sympathies and everyday abuse, so expect it to break at some time and carry a spare. With the best will in the world, what we plan to do as sympathetic bike owners with the up-keep of our bikes, tends to fall much short of our actions.

One more thing; mechanics get it wrong too! Just because the local LBS replaced your recently departed gear hanger with a fresh sparkly new one, it doesn’t mean that under pressure they diagnosed a fault at all, that they diagnosed it correctly or that they ensured they had used a DAG tool on the new hanger they just fitted before sending you home with your bike.

Time spent differs hugely from one LBS to another. If an LBS needs to diagnose why a gear hanger failed, expect to pay for labour time to do it. Its not just a gear hanger fitting charge. Given the nature of a gear hanger breaking, expect potential replacement parts from time to time too.

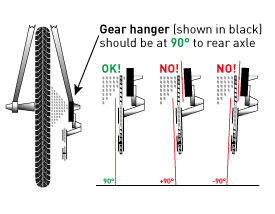

When we spend time checking an existing derailleur hanger or fitting a new derailleur hanger it is imperative that the derailleur is correctly aligned:

Of course, without a derailleur alignment gauge (DAG for short), hangers can sometimes be aligned in only one place and not another so full alignment should be checked and amended with a DAG. If you haven’t got one, invest in one, learn to use it properly. If not then your LBS probably will have one.

When and only when it’s fully aligned in both planes, the rear derailleur min/max stops should be reset. A new hanger will almost certainly sit in a slightly different position than an old one. Then follow with a full gear index and retune.

Don’t forget if any supplied screws are a tad on the longer side with your particular frame, file them down or take alternate action so they do not foul any other parts.

An excellent guide for some these topics can be found here with Park Tool:

https://www.parktool.com/blog/repair-help/rear-derailleur-adjustment

The alignment process applies whether you are replacing a damaged hanger as described above OR replacing a hanger simplify for aesthetic or performance purposes.

It goes without saying that we would recommend a rear derailleur hanger is fitted by a suitably qualified or experienced individual, perhaps your LBS or local mechanic, but with someone who in all cases is familiar with the aforementioned processes.

Above all stay safe, stay upright (unless you really meant not to!) and enjoy your riding!